Transmitting Rotation in Vacuum Systems

Principles of a Ferrofluid Rotary Vacuum Seal

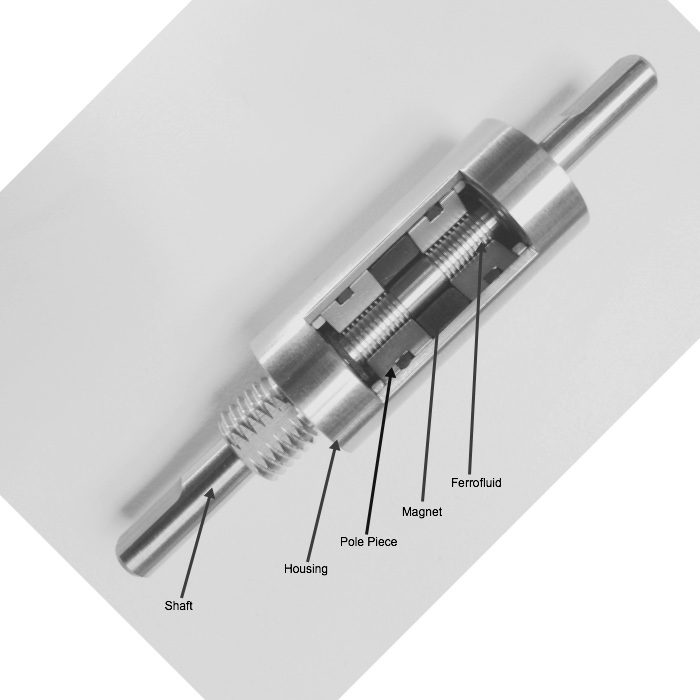

Design

A Ferrofluid Rotary Vacuum Feedthrough uses the response of a magnetic fluid with an applied magnetic field to transmit rotation into a high vacuum or ultra-high vacuum system. Rotary vacuum seal components include the liquid ferrofluid, permanent magnet, two pole pieces and a magnetically permeable shaft. The magnetic circuit employs stationary pole pieces and the rotating shaft, and concentrates magnetic flux in the radial gap under each pole piece.

Operation

Once the ferrofluid is applied to the radial gap, the ferrofluid takes the shape of a liquid O-ring and produces a hermetic vacuum seal. Ferrofluidic vacuum rotary feedthroughs use multiple fabricated rings or grooves with ferrofluid, located in stages, formed by grooves machined into either the shaft or pole pieces. Typically each single stage or groove can sustain a pressure differential of 0.2 atmospheres (200 mbar). The total vacuum pressure achieved is the sum of all the differential pressures provided by the grooves.

Ferrofluidic Feedthrough Products

Hermetic High Vacuum Seal

The Ferrofluid Rotary Vacuum Seal provides a hermetic atmospheric to high vacuum rotary vacuum seal under both static and dynamic conditions; providing protection from gas, vapor and other contaminants. The Leakage rate specification is 1 x 10‐9 std. cc/sec. All ferrofluid rotary vacuum seals are helium leak checked with a helium mass spectrometer. Rotary seals with ConFlat (CF) flanges are designed as a UHV rotary feedthrough.

Longevity

In the Ferrofluid Feedthrough, the Ferrofluid Rotary Vacuum Seal is formed using the ferrofluid resulting in minimal to no friction. Additionally, there are no wear parts that can break off and contaminate the vacuum system. The ferrofluid is inert and stable with low vapor pressure. The lifetime of the seal is dependent on the application, but a 10+ year between maintenance time-frame is not unexpected.

Strong Reliability

The Ferrofluid seal contains a simple permanent magnetic circuit and low volatility ferrofluid. The only wear parts are the self-contained ball bearings. These ball bearings are designed for a durable high speed transmission and a long lifetime.

Non-Contaminating

Unlike O-ring Vacuum Seals, there is a lack of mechanical friction in the seal. No particles that could contaminate the vacuum system are produced. Low vapor pressure ferrofluids maintain seal integrity better than 10-9 mbar, even in high vacuums.

High Speed Capability

Ferrofluid seals provide hermetic vacuum sealing at high rotational speeds (>10,000 rpm) with smooth motion.

No Leakage

Ferrofluid seals provide leak-free performance, even in intermittent and static rotating conditions. Elastomeric seals can be susceptible to plasticizing and relaxation effects during idle periods.

Click to Download the Apex Ferrofluid Catalog

Cross Reference Chart to Other Brands

Standard Specification:

Leak rate: 1 x 10‐9 std. cc/sec, He

Vacuum range: 8 x 10‐7 Torr

Max. operation pressure: 28 psi

Bearing lubrication: Fomblin / Krytox

Specification for CF flange

Leak rate: 1x10‐11 std cc/sec, He Vacuum range: 5x10‐10 Torr

Standard ferrofluid

Base oil: Hydrocarbon

Max. operation temperature: 0‐80 °C

Reactive gas ferrofluid

Base oil: Perfluorinated Polyether